Investment Casting

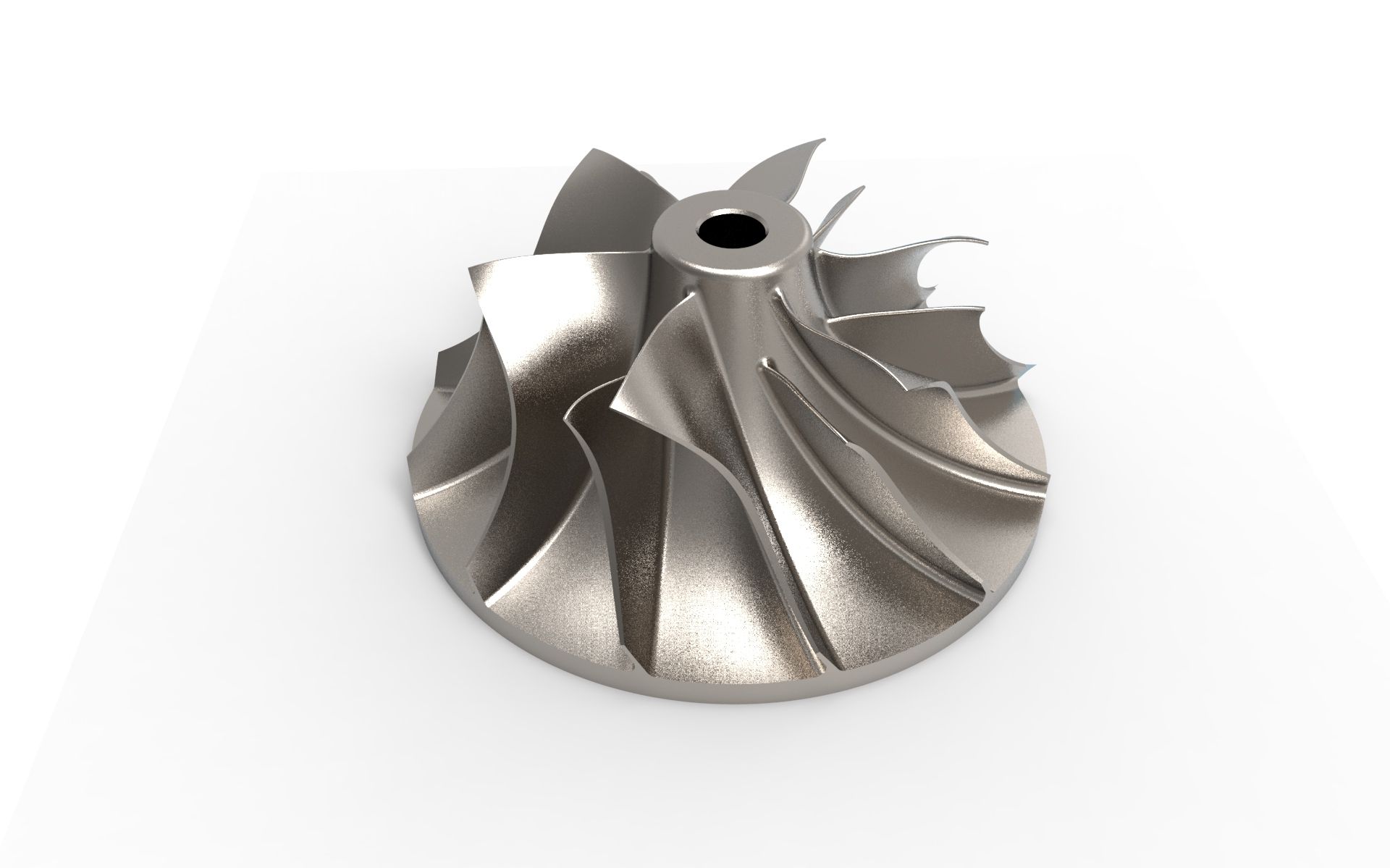

Manufacture intricate design features and complex geometries much better than any other casting process using Custiv’s Investment casting solutions. Usually done for small to medium production runs. It is also called as lost wax casting, as a wax pattern is made and the real mould is made around and the wax is drained out. Your casted component will have a high degree of complexity in features and surfaces. Investment casting has found applications in aerospace, power generation and Automotive industry. It is the most popular choice to manufacture rotor like components. Investment casting also produces parts with great surface finish and requires very few post processing steps to get a finished part. Custiv’s 10+ Investment Casting foundries can help you manufacture investment casted parts in almost any material, including steel alloys, aluminium and titanium, with the least possible lead times and cost.